- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

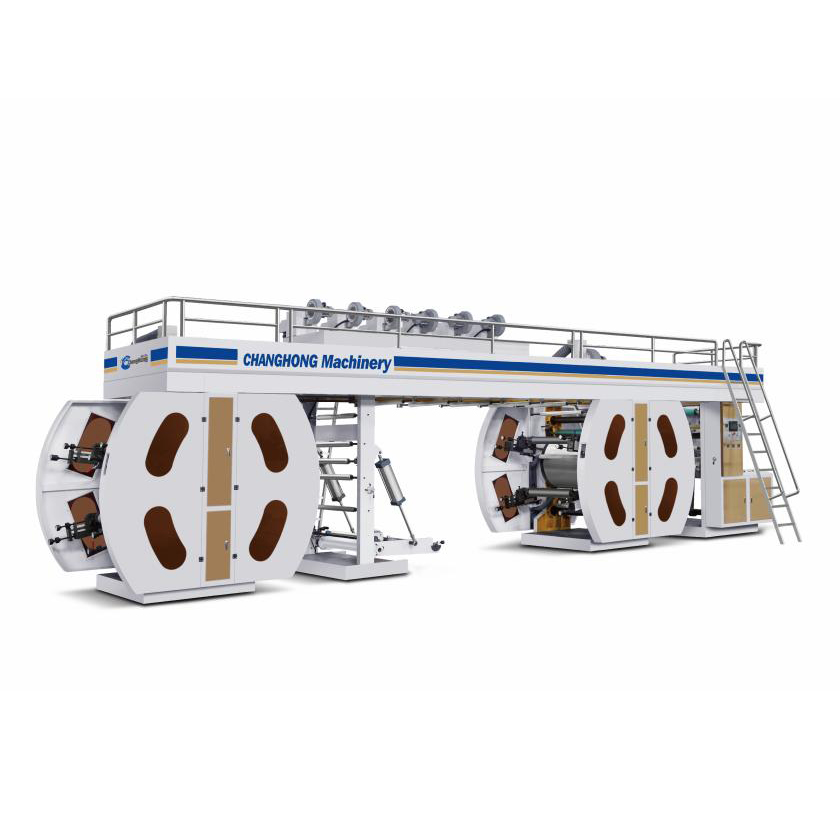

China wholesale With Water Ink Printing Machine Suppliers – 8 Colors Central Drum Flexo Printing Machine – Changhong Printing

China wholesale With Water Ink Printing Machine Suppliers – 8 Colors Central Drum Flexo Printing Machine – Changhong Printing

China wholesale With Water Ink Printing Machine Suppliers – 8 Colors Central Drum Flexo Printing Machine – Changhong Printing Detail:

Central Drum Flexo Printing Machine is mainly composed of unwinding part, input part, printing part (CI type), drying and cooling part, connecting line” Printing and processing part, output part, winding or stacking part, control and management part and auxiliary equipment part.

| Model | CHCI8-600S | CHCI8-800S | CHCI8-1000S | CHCI8-1200S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | 50-400g/m2 Paper. Non woven Etc. | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

(1) The substrate can pass multiple times on the impression cylinder at one time color printing.

(2) Because the roll-type printing material is supported by the central impression cylinder, the printing material is tightly attached to the impression cylinder. Due to the effect of friction, the elongation, relaxation and deformation of the printing material can be overcome, and the overprinting accuracy is ensured. From the printing process, the printing quality of the round flattening is the best.

(3) Wide range of printing materials. The applicable paper weight is 28~700g/m. Applicable plastic film varieties are BOPP, OPP, PP, HDPE, LDPE, soluble PE film, nylon, PET, PVC, aluminum foil, webbing, etc. can be printed.

(4) The printing adjustment time is short, the loss of printing materials is also less, and the raw materials are consumed less when adjusting the printing overprint.

(5) The printing speed and output of the satellite flexo press are high.

.png)

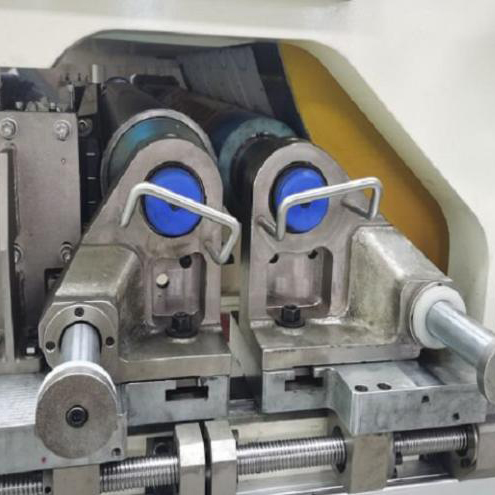

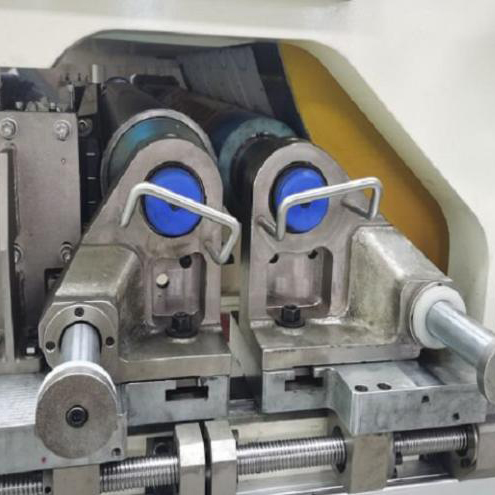

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for China wholesale With Water Ink Printing Machine Suppliers – 8 Colors Central Drum Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Sacramento, Russia, New Zealand, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.