- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

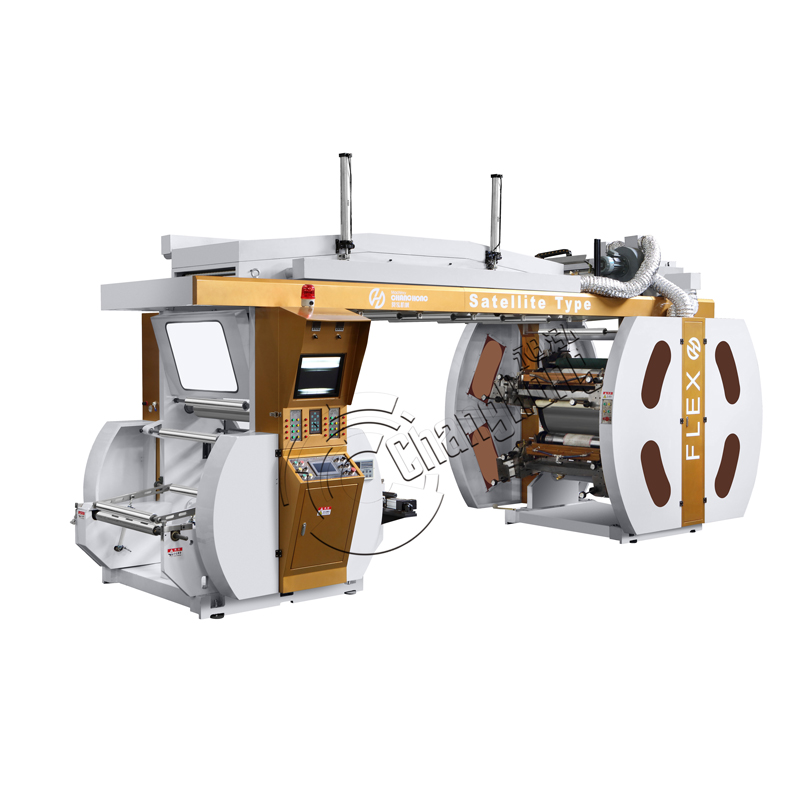

China wholesale Central Impression Flexo Press Factory – 6 Colour CI Flexo Printing Machine – Changhong Printing

China wholesale Central Impression Flexo Press Factory – 6 Colour CI Flexo Printing Machine – Changhong Printing

China wholesale Central Impression Flexo Press Factory – 6 Colour CI Flexo Printing Machine – Changhong Printing Detail:

The ci flexo printing machine sometimes becomes a common embossed cylinder flexo printing machine. Each printing unit is installed between two wall panels around a common embossing cylinder. The printed material is used for color printing around normal embossing rolls. Due to the direct drive of the gears, whether it is paper or film, even without special control devices, it can still register accurately and the printing process is stable.

The following is the whole workflow of printing paper material with Ci flexo printing machine.

|

TECHNICAL SPECIFICATIONS |

||||

| Model | CHCI6-600E | CHCI6-800E | CHCI6-1000E | CHCI6-1200E |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

1. The ceramic anilox roller is used to accurately control the amount of ink, so when printing large solid color blocks in flexographic printing, only about 1.2g of ink per square meter is required without affecting color saturation.

2. Due to the relationship between the flexographic printing structure, ink, and amount of ink, it does not require too much heat to completely dry the printed job.

3. In addition to the advantages of high overprinting accuracy and fast speed. It actually has a very big advantage when printing large-area color blocks (solid).

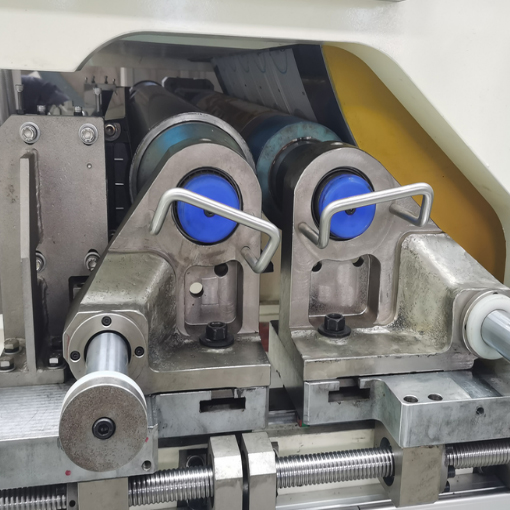

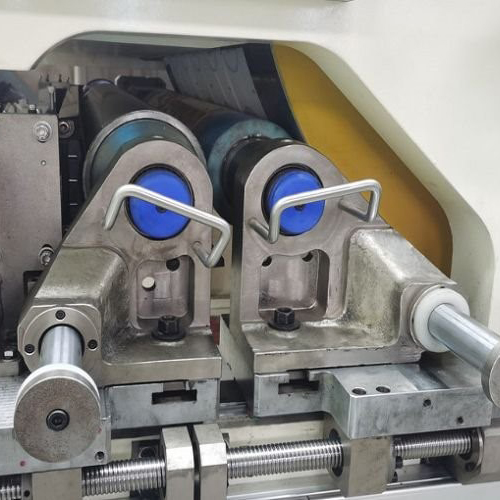

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for China wholesale Central Impression Flexo Press Factory – 6 Colour CI Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Hyderabad, South Korea, Senegal, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We are looking forward to customers from all over the world to join us to a wild cooperation.