- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

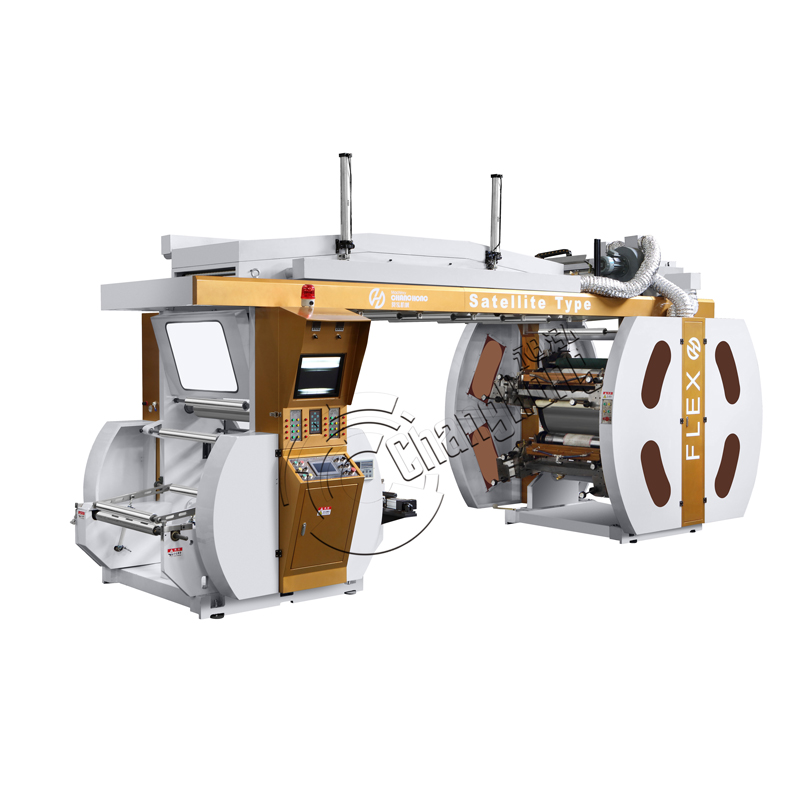

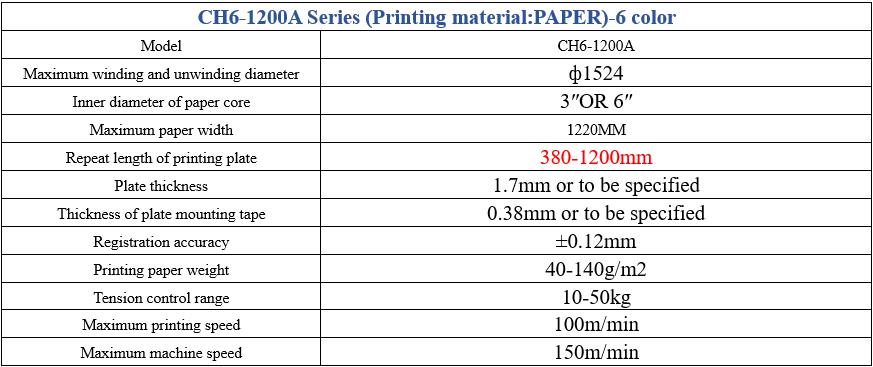

Best High Quality Wrapper Printing Machine Factories – Paper cup flexo printing machine – Changhong Printing

Best High Quality Wrapper Printing Machine Factories – Paper cup flexo printing machine – Changhong Printing

Best High Quality Wrapper Printing Machine Factories – Paper cup flexo printing machine – Changhong Printing Detail:

The printing units of each color are independent of each other and arranged horizontally, and are driven by a common power shaft. The printing unit is called Inline Flexo Printing Machine, which is the standard model of modern flexo printing presses.

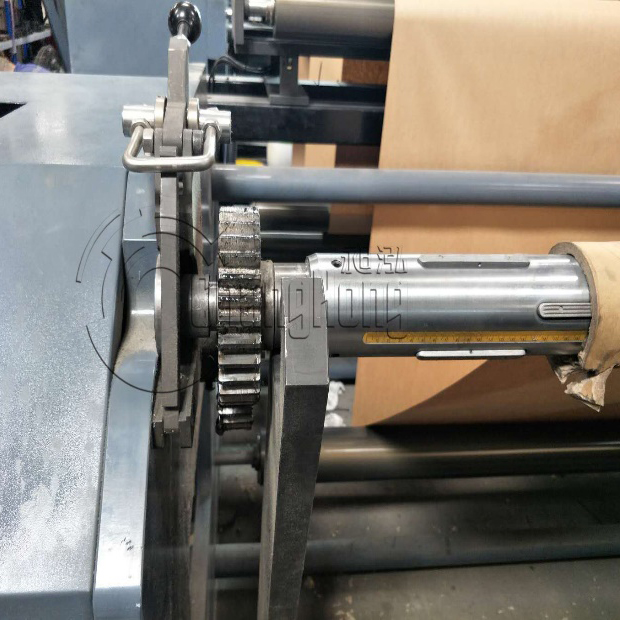

The following is the operation flow of Flexographic printing machine unwinding and rewinding

1.The In Line Flexo Printing Machine enables double-sided printing by changing the conveying route of the substrate.

2.The printing material can be a single sheet of paper, cardboard, corrugated paper and other rigid materials, or can be a roll type of materials such as self-adhesive paper and newspapers.

3.The Inline Flexo Printing Machine has strong post-press capabilities. Arranged flexo printing units can facilitate the installation of auxiliary equipment.

4.Inline flexo press In addition to completing multi-color printing, it can also be coated, varnished, hot stamped, laminated, punched, etc. Forming a production line for flexographic printing.

5.Large area and high technical level requirements.

6.It can be combined with a gravure printing machine unit or a rotary screen printing machine as a printing production line to enhance the anti-counterfeiting function and decorative effect of the product.

In line flexo printing machine is mainly used for the printing of paper materials such as paper cups.

Product detail pictures:

Related Product Guide:

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Best High Quality Wrapper Printing Machine Factories – Paper cup flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: Mumbai, Sudan, Florence, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.