- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

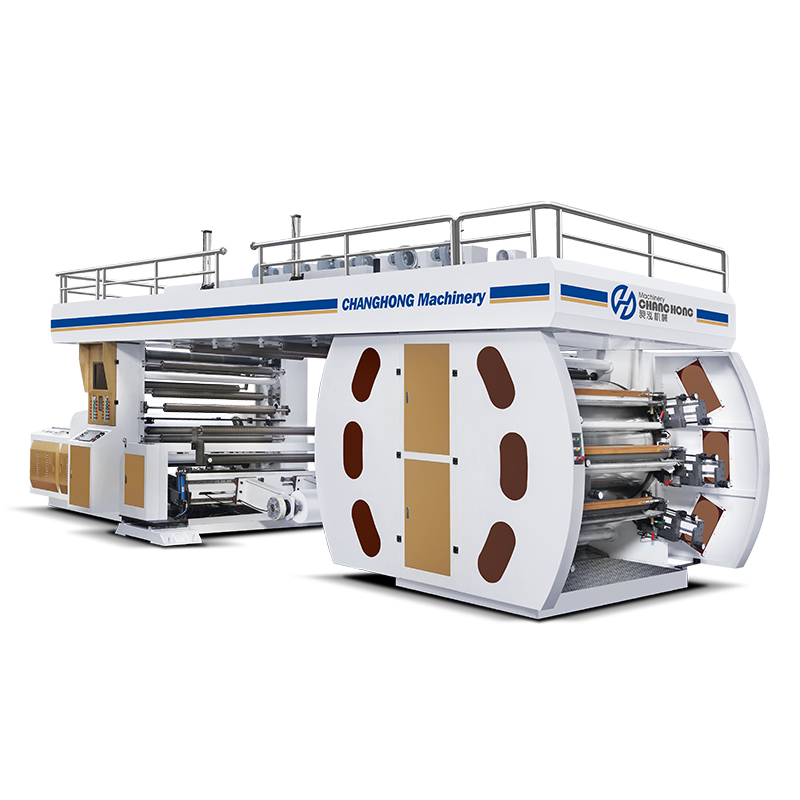

Best High Quality Poly Bag Printing Machine Manufacturer – 4+4 CI Flexo Printing Machine – Changhong Printing

Best High Quality Poly Bag Printing Machine Manufacturer – 4+4 CI Flexo Printing Machine – Changhong Printing

Best High Quality Poly Bag Printing Machine Manufacturer – 4+4 CI Flexo Printing Machine – Changhong Printing Detail:

Product Video

Machine Process Flow

Body: Material: cast iron. The thickness of the machine plate is 100mm.

No vibration at high speed, accurate color register, long service life.

Mechanical structure: Integral wallboard, big central drum, precision helical gear, high precision and good equipment stability.

Drive way: The whole machine adopt servo motor, linkage and register more accuracy.

Tension mode: The whole machine choose closed-loop control and low friction cylinder device to make tension constant.

Control mode: Modular design, centralized electric cabinet, touch screen centralized control.

Uwinding part: The double station with non-stop feeding. Automatic deviation correction. Material cut detection. Coil diameter detection. Alarmwhen change the reel.

Printing part: High precision printing roller and ceramic anilox roller. Chamber doctor blade. So that the machine can prinT high precision product with high speed.

Drying method: Separate electric heating box does the circulation heating. It is safety, environmental and energy saving.

Rewinding part: The double station with non-stop feeding. Automatic deviation correction. Vibration rewinding. Servo cutting.

It starts to print when the plate is pasted and registered. Do not need registration again, so as to improve the rate of finished products.

The maximum speed of the production machine can reach 150m / min, the registration accuracy is ± 0.15mm, and the registration accuracy will not change when the printing speed is different.

Adopt Taiwan motor, save power and run smoothly.

Adopt ceramic anilox roll (250-500lpi) from Japan. High productivity, good printing quality and accurate color register.

Each color all has an independent small motor to keep the ink stable, reduce printing defects and keep the consistency of printing products. It can reduce ink consumption and production cost greatly.

Automatic rewinding edge correction: We choose automatic edge correction device. When the machine stops, the tension can be maintained and the base material will not deviate or shift.

Aluminum alloy guide wheel: hard oxidation, dynamic balance and static balance treatment.

Drying device: Equipped with hot air drying and cold air setting bellows, which can effectively prevent ink adhesion or other defects after printing.

Bearing: Japan NSK one-way bearing, Germany ASNU aluminum alloy guide wheel, hard oxidation, dynamic balance and static balance treatment.

Advantage: Structural precision. Easy operation. Convenient maintenance. High degree of automatio, ETC. The machine can be operated by only one person.

Features:

1. This machine introduction & absorption of European technology precess manufacturing

2.After mounting the plate, the registration, no longer need registration, improve yield

3. The machine is equipped with blower and heater, and the heater empolyed central temperature control system

4. When machine stop, tension can be maintained, the substrate is not deviation shift

5. The individual drying oven and cold wind system can effectively prevent the ink adhesion after printing

Suitable material:

Two drum rolling type

Printing material, PP woven

Suitable water -base ink or solvent ink.

Suitable: Photopolymer plate 1.7mm or 2.28mm (As customer requirement).

Machine Production technology:

Double unwind unit→ Automatic tension control→ Automatic EPC 2pcs for unwind, 1pcs for rewind→Two printing Unit(4+4colors)→ Dry system after printing→ Automatic tension control → Single rewind unit

Main Parameter

| Model | CHCI8-800T |

| Printing color | 4+4color |

| Max web width | 850mm |

| Max Printing width | 750mm |

| Printing repeat | 400-1200mm |

| Max Machine speed | 150m/min |

| Max Printing speed | 120m/min |

| Register precision | Longitudinal: ±0.15mm ; Transverse: ±0.15mm |

| Master motor | 7.5Kw |

| The frequency converter | 11KW |

| PLC | 1set |

| Machine total power | About 80KW |

| Machine weight | About 12000KG |

| Machine size | L15600*W2500*H3600 |

| Machine voltage | 3Phase, 380V, 50HZ(As customer requirement) |

Process Flow Diagram

Detailed Machines Pictures

Printing Sample

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Best High Quality Poly Bag Printing Machine Manufacturer – 4+4 CI Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Curacao, New Zealand, Libya, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our merchandise and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".