- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

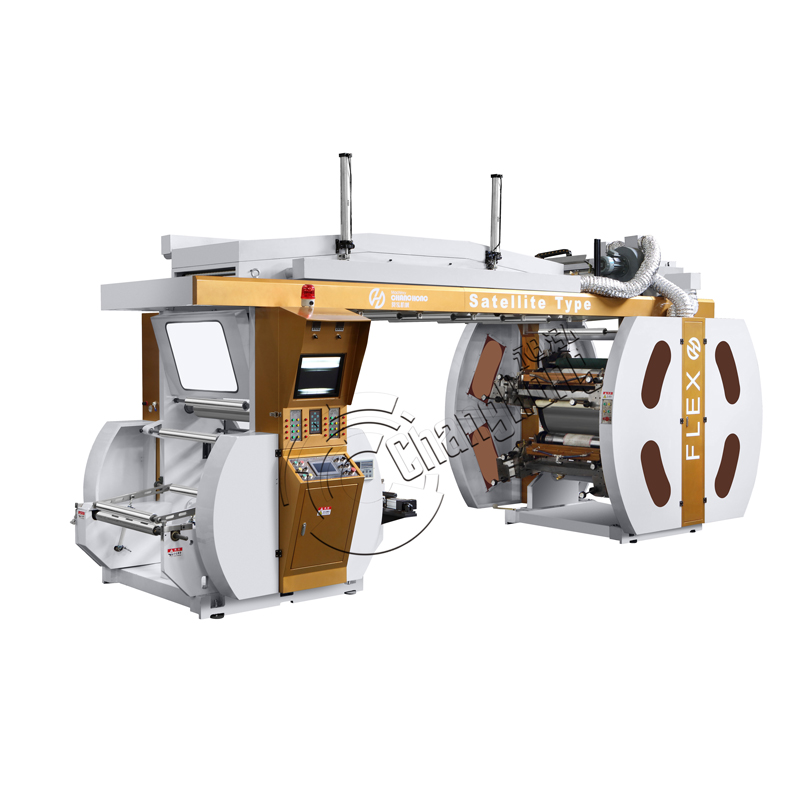

Best High Quality Plastic Printer Machine Suppliers – Shrink Film/PET/NY/ Stack type flexo printing machine – Changhong Printing

Best High Quality Plastic Printer Machine Suppliers – Shrink Film/PET/NY/ Stack type flexo printing machine – Changhong Printing

Best High Quality Plastic Printer Machine Suppliers – Shrink Film/PET/NY/ Stack type flexo printing machine – Changhong Printing Detail:

| Model | CH-600H | CH-800H | CH-1000H | CH-1200H |

| Max. Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 120m/min | |||

| Printing Speed | 100m/min | |||

| Max. Unwind/Rewind Dia. | φ1000mm or φ1200mm( can according to your requirement) | |||

| Drive Type | Gear drive/Belt Drive( According to your requirement) | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 270mm-900mm | |||

| Range Of Substrates | PAPER,NON WOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or as your requirement to make it | |||

1. Unwind unit adopts single-station or double-station structure; 3″air shaft feeding; Automatic EPC and constant tension control;With refueling warning, break material stop device.

2. The main motor is controlled by frequency conversion, and the whole machine is driven by high-precision synchronous belt or servo motor.

3. The printing unit adopts ceramic mesh roller for ink transfer, single blade or chamber doctor blade, automatic ink supply; Anilox roller and plate roller automatic separating after stop; The independent motor drives the anilox roller to prevent ink from solidifying on the surface and blocking the hole.

4. Rewinding pressure is controlled by pneumatic components.

5. Rewind unit adopt single-station or double-station structure; 3 “air shaft; Electric motor drive, with closed – loop tension control and material – breaking stop device.

6. Independent drying system: electric heating drying (adjustable temperature).

7. The whole machine is centrally controlled by PLC system; Touch screen input and display the working state; automatic meter counting and multi – point speed regulation.

Product detail pictures:

Related Product Guide:

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for Best High Quality Plastic Printer Machine Suppliers – Shrink Film/PET/NY/ Stack type flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: Jordan, Brazil, Pretoria, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.