- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

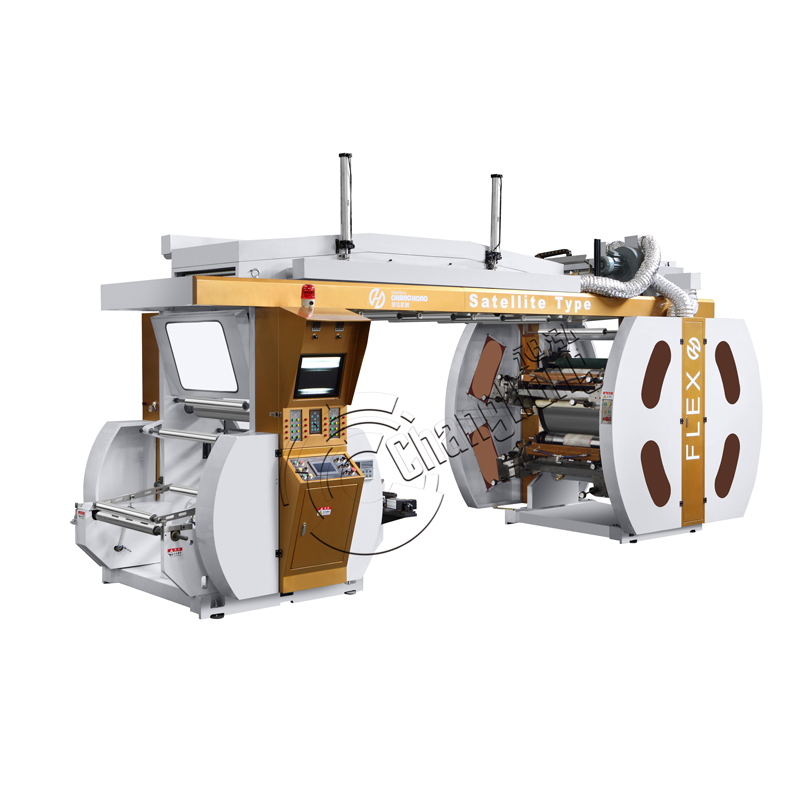

Best High Quality Paper Printing Machine Supplier – 4 Colour CI flexo printing machine – Changhong Printing

Best High Quality Paper Printing Machine Supplier – 4 Colour CI flexo printing machine – Changhong Printing

Best High Quality Paper Printing Machine Supplier – 4 Colour CI flexo printing machine – Changhong Printing Detail:

All printing units of Ci flexo printing machine share one impression cylinder. Each plate cylinder rotates around a large diameter impression cylinder. The substrate enters between the plate cylinder and impression cylinder. It rotates against the surface of the impression cylinder to complete multi-color printing.

The following is an introduction to the workflow of unwinding and rewinding of the Plastic film flexo printing machine.

| TECHNICAL SPECIFICATIONS | ||||

| Model | CHCI4-600E | CHCI4-800E | CHCI4-1000E | CHCI4-1200E |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

1.The ink level is clear and the printed product color is brighter.

2. Ci flexo printing machine dries almost as soon as the paper is loaded due to the water-based ink printing.

3.CI Flexo Printing Press is easier to operate than offset printing.

4.The overprinting precision of the printed matter is high, and the multi-color printing can be completed by one pass of the printed matter on the impression cylinder

5.Short printing adjustment distance, less loss of printing material.

Film flexo printing machine has a wide range of printing fields. In addition to printing various plastic films such as /PE/Bopp/Shrink film/PET/NY/, it can also print non-woven fabrics, paper and other materials.

.png)

Changhong Flexo printing machines have passed ISO9001 international quality system certification and EU CE safety certification, etc.

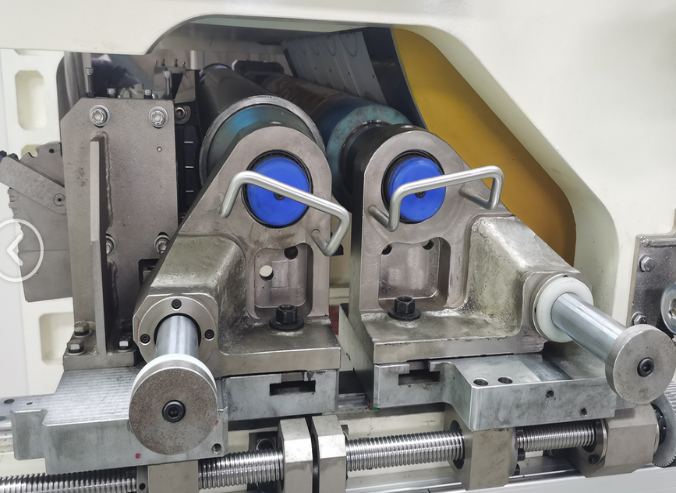

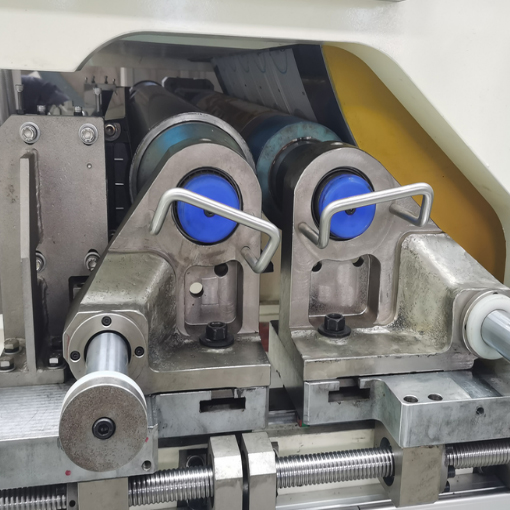

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our progress strategy for Best High Quality Paper Printing Machine Supplier – 4 Colour CI flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: Chicago, Slovenia, Russia, We have 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export products to other countries. We expect to cooperate with you to develop a larger market.