- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

Best High Quality Machine To Print On Plastic Bags Suppliers – 4 Colour Stack Flexo Printing Machine – Changhong Printing

Best High Quality Machine To Print On Plastic Bags Suppliers – 4 Colour Stack Flexo Printing Machine – Changhong Printing

Best High Quality Machine To Print On Plastic Bags Suppliers – 4 Colour Stack Flexo Printing Machine – Changhong Printing Detail:

| Model | 600 | 800 | 1000 | 1200 | 1400 |

| Max. Material width | 650mm | 850mm | 1050mm | 1250mm | 1450mm |

| Max. Printing width | 560mm | 760mm | 960mm | 1160mm | 1360mm |

| Printing color | 6+0, 5+1, 4+2, 3+3 | ||||

| Printing length | 11.8”-35.4”(300-900mm)/11.8”-47.2”(300-1200mm) | ||||

| Printing cylinder way | Hydraulic control up and down | ||||

| Drive type | Synchronous belt drive | ||||

| Mechanical speed | 135m/min | ||||

| Printing speed | 10-90m/min | ||||

| Anilox roller | (1) Metal anilox roller 6pcs:100-300LPI (2) Ceramic anilox roller 6pcs: 200-800LPI Open type doctor blade 6pcs |

||||

| Tension system | Automatic tension controller with magnetic powder brake and clutch | ||||

| EPC | Web guide 1pcs | ||||

| Register precision | Longitudinal:±0.2mm crosswise:±0.2mm; | ||||

| Color register | By manual | ||||

| Unwind/rewind dia. | Φ1000mm/Φ1200mm/Φ1500mm | ||||

| Material holder | Air shaft 3”, 2pcs | ||||

| Dry system | Electric heating | ||||

| Machine power | 30kw | 32kw | 34kw | 38kw | 40kw |

1.Stack type flexo printing machine can do double-sided printing in advance, and can also print in single color or multiple colors.

2. The stack flexo printing machine can use paper of various materials for printing, even in roll form or self-adhesive paper.

3. The Stack flexo press can also perform various operations and maintenance, such as machining, die cutting and varnishing operations.

4. The stacked flexographic printing machine can also be used for multiple purposes, and can process many special prints, so it can be seen that its superiority is very high. Of course, the lamination flexographic printing machine is advanced and can help users to automatically control the system of the printing machine itself by setting the tension and registration.

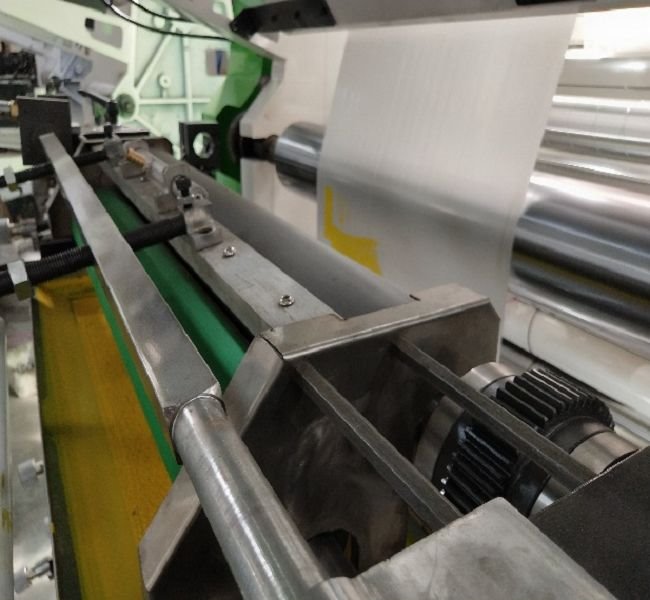

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for Best High Quality Machine To Print On Plastic Bags Suppliers – 4 Colour Stack Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Danish, Italy, Sri Lanka, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.