- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

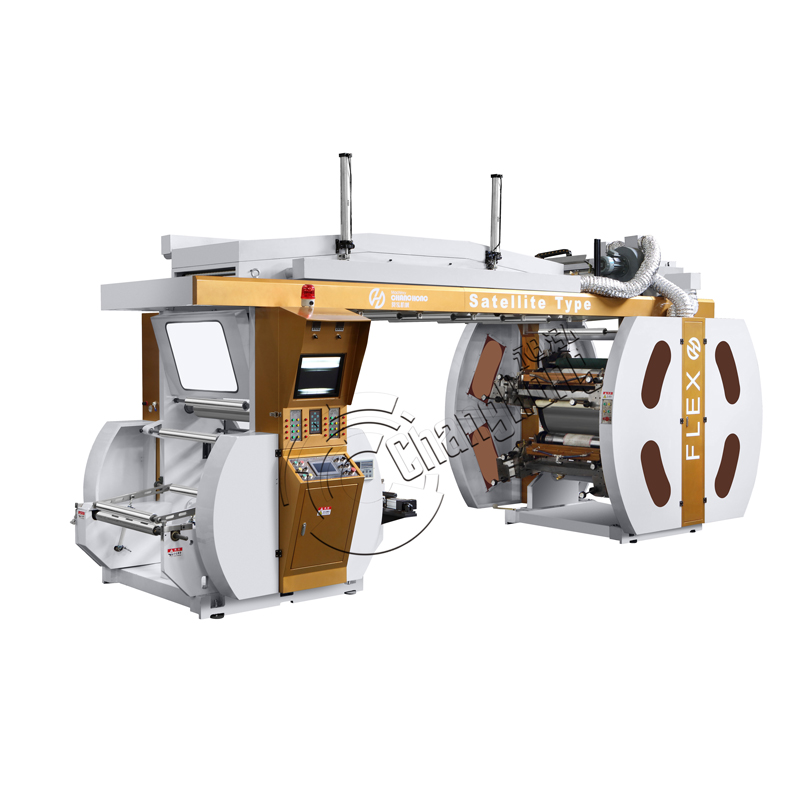

Best High Quality Logo Machine Printer Manufacturer – Kraft paper/Paper cup/flexo printing machine – Changhong Printing

Best High Quality Logo Machine Printer Manufacturer – Kraft paper/Paper cup/flexo printing machine – Changhong Printing

Best High Quality Logo Machine Printer Manufacturer – Kraft paper/Paper cup/flexo printing machine – Changhong Printing Detail:

The Inline flexo printing machine includes an unwinding stand and a rewinding stand, as well as several printing units arranged in sequence between the unwinding stand and the reeling stand. When the printing machine is printing, the printing plate cylinder is inked on the entire layout, and the layout is covered with a squeegee. The ink in the blank part is scraped off, leaving the ink in the graphic part, and then it passes through the paper and is imprinted on the back of the paper by the impression cylinder, so that the ink in the concave part is directly transferred to the paper surface, and finally the printed matter is passed through the delivery part. Stack or rewind well.

1. In line flexo printing machine adopts ceramic anilox roller to transfer ink, the ink transfer is uniform, and there is no color difference in printing.

2. Using three-stage tension control, the printing tension is stable and the set position is accurate.

3. Applicable ink: water-based ink, UV ink, solvent-based ink.

4. Automatic drying, automatic winding once completed, easy to replace printing plate, simple pressure adjustment, stable operation, suitable for large-scale printing dramas.

5.Paper flexo printing machine units are flexible and convenient to install and combine, and the number of units can be increased or decreased according to the different needs of users.

6.Unwinding uses magnetic powder braking and automatic tension control to achieve constant tension control

7.The host adopts frequency conversion control, and the transmission is synchronous belt transmission .

8.Quickly change the printing plate cylinder and stainless steel ink cartridge without any tools.

9.Inline flexo press adopts PLC control, with self-diagnosis function to monitor machine status.

In line flexo printing machine is mainly used for the printing of paper materials such as paper cups.

Product detail pictures:

Related Product Guide:

Our enhancement depends around the sophisticated devices ,exceptional talents and repeatedly strengthened technology forces for Best High Quality Logo Machine Printer Manufacturer – Kraft paper/Paper cup/flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: New York, Porto, Ghana, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.