- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

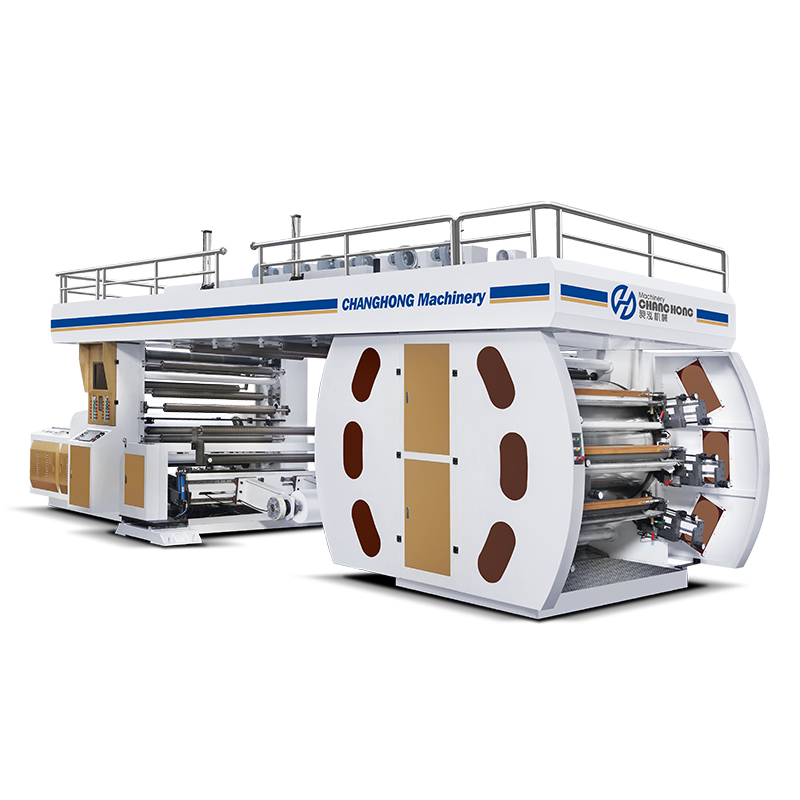

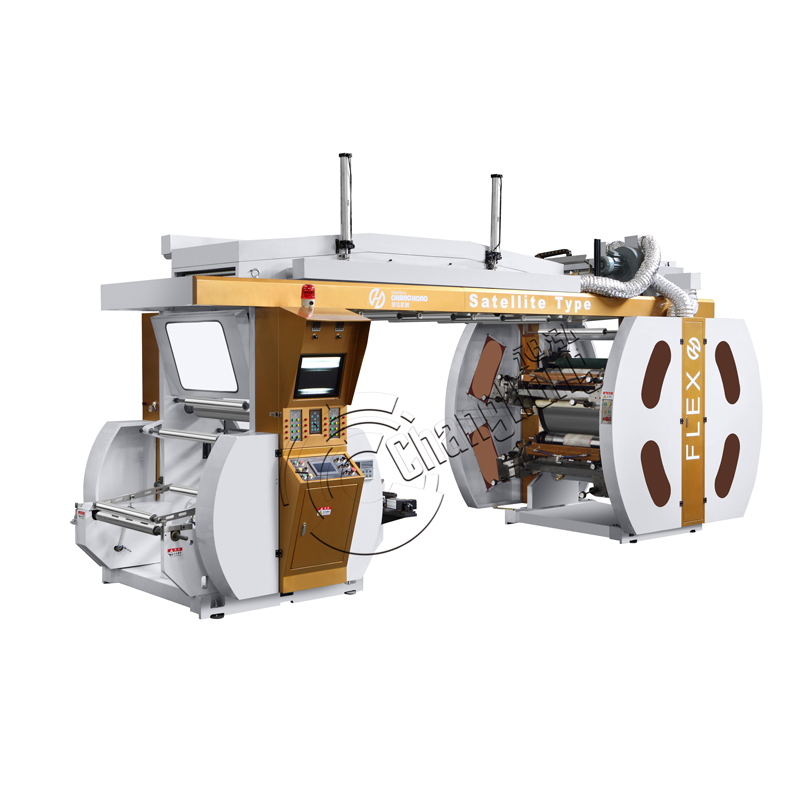

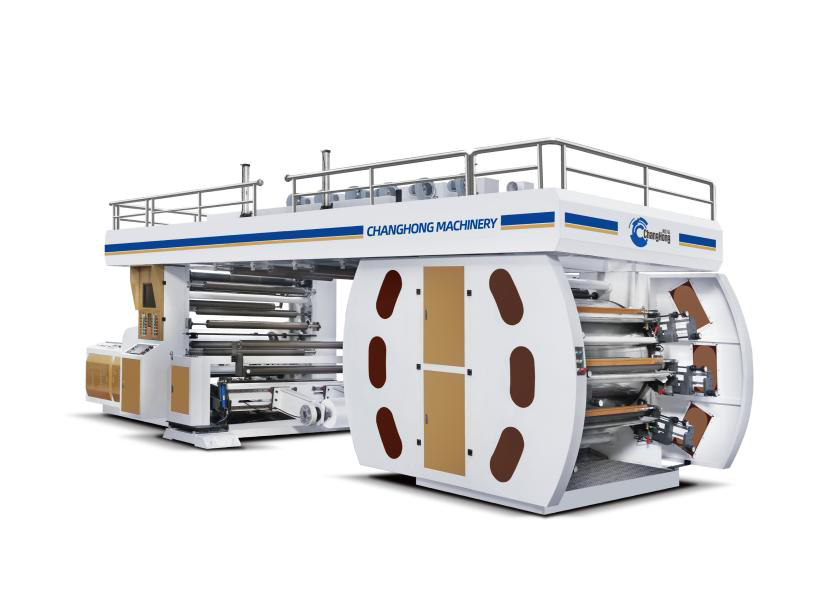

Best High Quality Letterpress Printing Machine Manufacturer – Paper Flexo Printing Machine – Changhong Printing

Best High Quality Letterpress Printing Machine Manufacturer – Paper Flexo Printing Machine – Changhong Printing

Best High Quality Letterpress Printing Machine Manufacturer – Paper Flexo Printing Machine – Changhong Printing Detail:

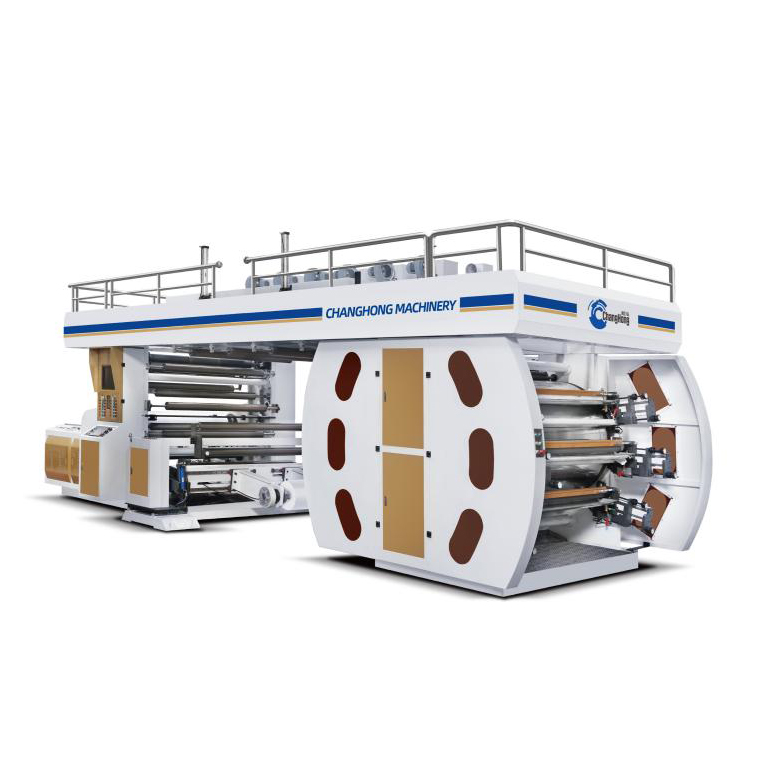

Central Drum CI type flexo printing machine is designed for stretchable materials as plastic film ,paper,and non woven fabric printings. Machine with Servo control, applies with water-based ink, achieves environmentally friendly, high precision and low pollution. Machine advanced features in efficiency operation and production cost savings. Also, it is very flexible in customerized of printing after-line function extensions and maximally meet customer demands in production.

| Model | CHCI8-600S | CHCI8-800S | CHCI8-1000S | CHCI8-1200S |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 300m/min | |||

| Printing Speed | 250m/min | |||

| Max. Unwind/Rewind Dia. | φ1200mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | 50-400g/m2 Paper. Non woven Etc. | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

● Central Drum impression cylinder with double wall constant temperature cooling circulation design.

● 100mm extreme thickness frame to ensure the stability of printing operation.

● Independent dryer between printing units for high drying efficiency.

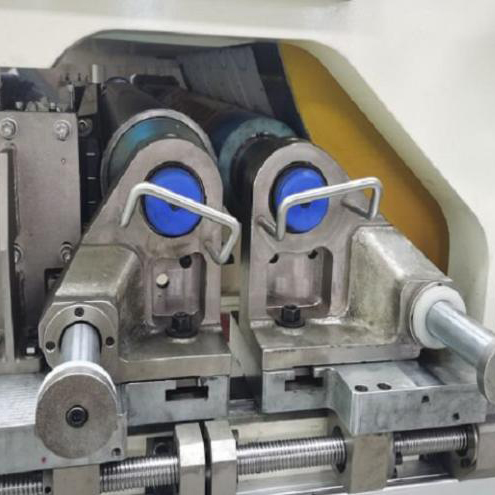

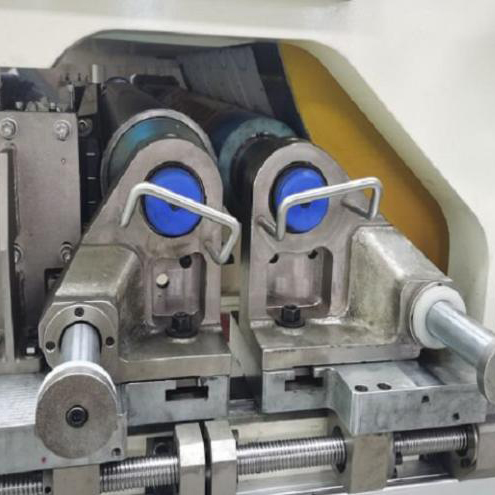

● Sleeve design printing cylinder and anilox roll for fast change over.

● Servo motor control in printing pressures.

● Pre-printing and automatic registration system — one step to print, achieves cost savings.

● Long-distance fault diagnosis function, diagnose and troubleshoot from the company base.

● Automatic unwind and rewind function for more efficiency in production and waste reducing.

● Surrounding type multi electrode corona treatment system helps film printing in better performance.

Product detail pictures:

Related Product Guide:

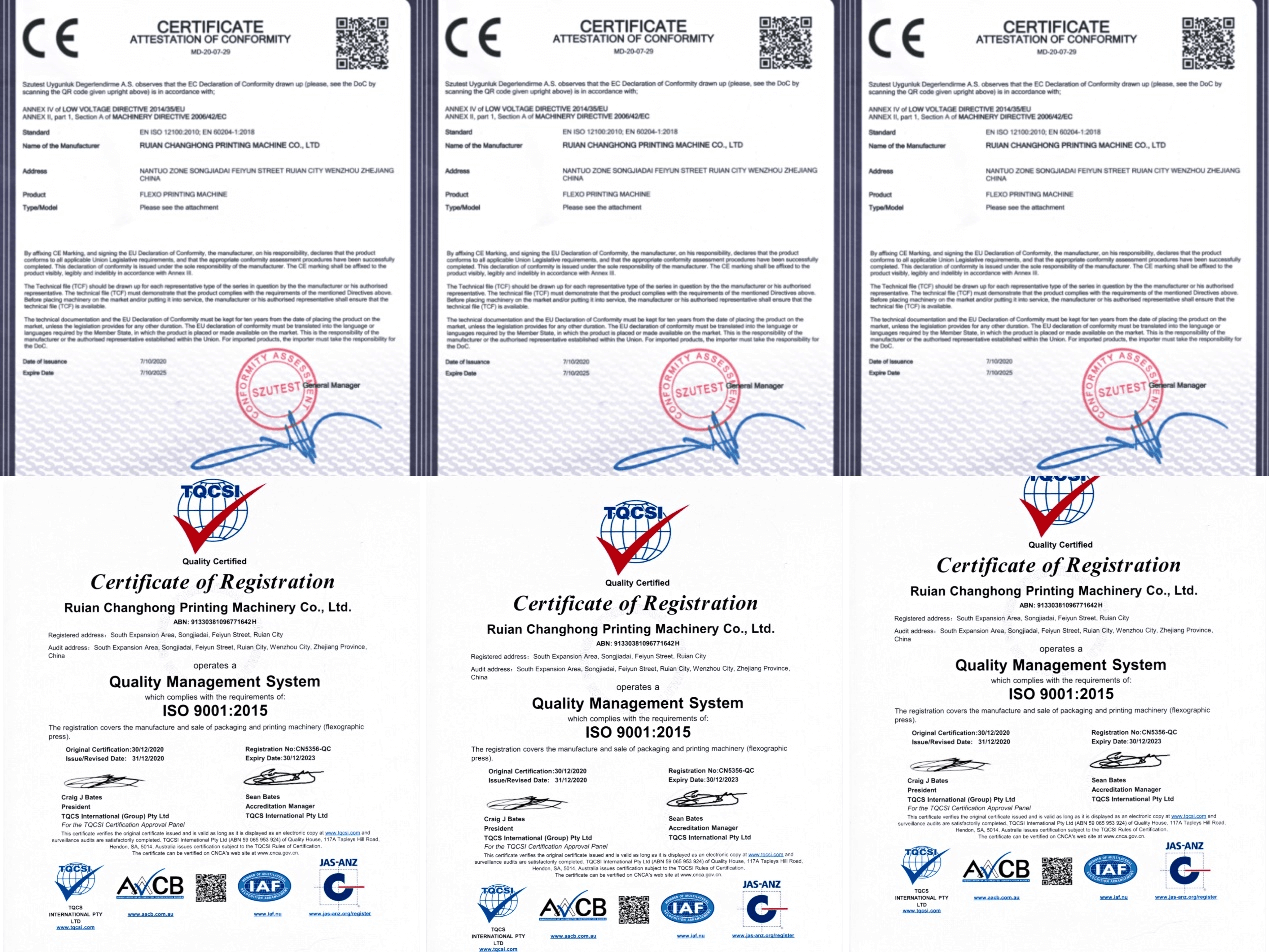

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for Best High Quality Letterpress Printing Machine Manufacturer – Paper Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Zambia, Cannes, Dubai, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our items, just try to contact us for more details!