- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

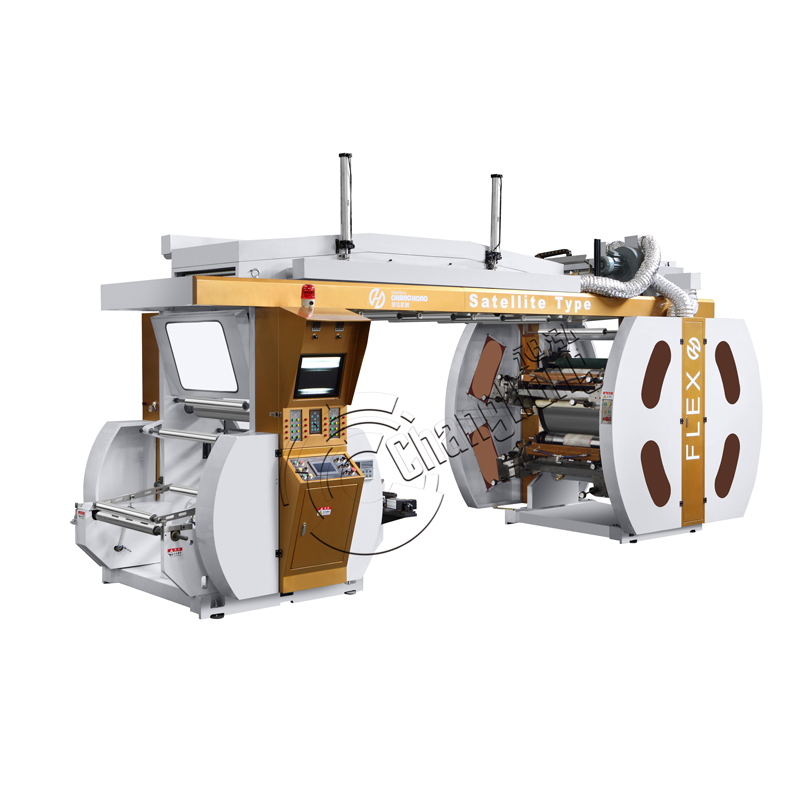

Best High Quality Flexographic Printing Equipment Factories – 6+6 CI Flexo Printing Machine – Changhong Printing

Best High Quality Flexographic Printing Equipment Factories – 6+6 CI Flexo Printing Machine – Changhong Printing

Best High Quality Flexographic Printing Equipment Factories – 6+6 CI Flexo Printing Machine – Changhong Printing Detail:

Product Video

Technical Specifications

Material: PP-woven, coated or uncoated

Max. printing material width: 850mm

Max. printing width: 750mm

Max. Printing length(repeat): 450–1200mm

Printing way: 6+6,6+5,6+4,6+3,6+2.6+1,6+0

Max machine speed:180 m/min

Max printing speed: 150m/min (According to material specifications, ink characteristics, printing design, printing roller, register quality, etc.)

Max. unwind diameter: 1500 mm

Max. rewind diameter: 1500mm

Ceramic anilox roller: 8 pcs (As customer requirement)

Thickness of Plate: Photopolymer plate 1.14mm(As customer requirement)

Double adhesive tape: 0.38mm

Cental drum:

Basic structure: it is a double-layer structure steel pipe, which is processed by multi-channel heat treatment and shaping process.

The surface adopts precision machining technology.

The surface plating layer reaches more than 100um, and the radial circle run out tolerance range is + / -0.01mm.

Dynamic balance processing accuracy reaches 10g

Mix ink automatically when the machine stops to prevent ink from drying

When the machine stops, the anilox roll leaves the printing roller and the printing roller leaves the central drum.But the gears are still engaged.

When the machine starts again, it will reset automatically, and the plate color registration / printing pressure will not change.

Electrical Parts:

Power: 380V 50HZ 3PH

Note: If the voltage fluctuates, u can use voltage regulator, otherwise the electrical components may be damaged.

Cable size: 50 mm² Copper wire

Electrical Spart part detail :

| PLC | Siemens, Germany |

| Main bearing | FAG, Germany/ NSK, Japan |

| Circuit-Breaker | CHINT. China |

| Rotary Switch | Schneider, Germany |

| E-stop Switch | Schneider, Germany |

| Inverter | Inovance, China |

| Button Switch | Schneider, Germany |

| Temperature controller | Yatai |

| Relay | Schneider, Germany |

| EPC | Made in China |

| Automatic Tension | Chuying, China |

| Main motor | Danma, China |

| Video | Kesai, China |

Process Flow Diagram

Detailed Machines Pictures

Printing Sample

Product detail pictures:

Related Product Guide:

Our merchandise are commonly recognized and reliable by customers and can meet constantly developing economic and social desires for Best High Quality Flexographic Printing Equipment Factories – 6+6 CI Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Curacao, Swedish, Nepal, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.