- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

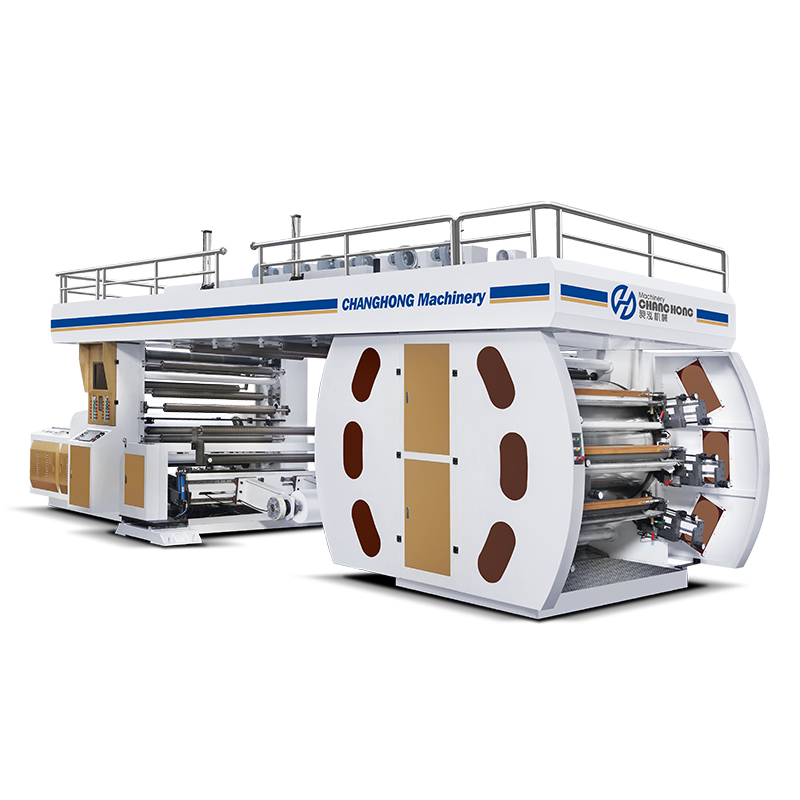

Best High Quality Flexo Digital Printing Machine Manufacturer – Non Woven Flexo Printing Machine – Changhong Printing

Best High Quality Flexo Digital Printing Machine Manufacturer – Non Woven Flexo Printing Machine – Changhong Printing

Best High Quality Flexo Digital Printing Machine Manufacturer – Non Woven Flexo Printing Machine – Changhong Printing Detail:

Non Woven Flexo Printing Machine is a printing machine that uses photosensitive resin soft plate (or rubber plate) as the plate material, commonly known as “flexo printing machine”, suitable for printing non-woven fabrics, paper, plastic films and other packaging materials, food paper packaging, clothing Ideal printing equipment for packaging such as bags. During printing, the ink is evenly coated on the raised pattern of the printing plate by the anilox roller, and the ink of the raised pattern is transferred to the substrate.

ChangHong Non Woven Flexo Printing Machine is easy to operate and has stable performance. The following is the running process of the machine.

| TECHNICAL SPECIFICATIONS | ||||

| Model | CHCI4-600J | CHCI4-800J | CHCI4-1000J | CHCI4-1200J |

| Max. Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 150m/min | |||

| Printing Speed | 120m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

1.The flexographic printing plate uses polymer resin material, which is soft, bendable and flexible.

2.Short plate making cycle, simple equipment and low cost.

3.It has a wide range of applications and can be used for the printing of packaging and decoration products.

4.High printing speed and high efficiency.

5.Flexographic printing has a large amount of ink, and the background color of the printed product is full.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Best High Quality Flexo Digital Printing Machine Manufacturer – Non Woven Flexo Printing Machine – Changhong Printing , The product will supply to all over the world, such as: Houston, United Arab Emirates, Libya, With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!