- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

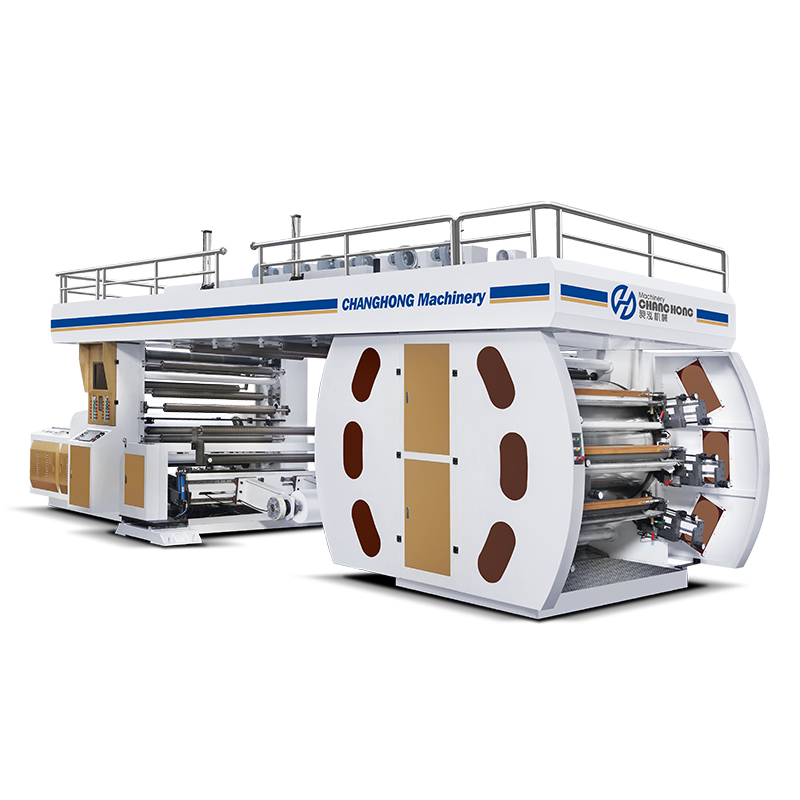

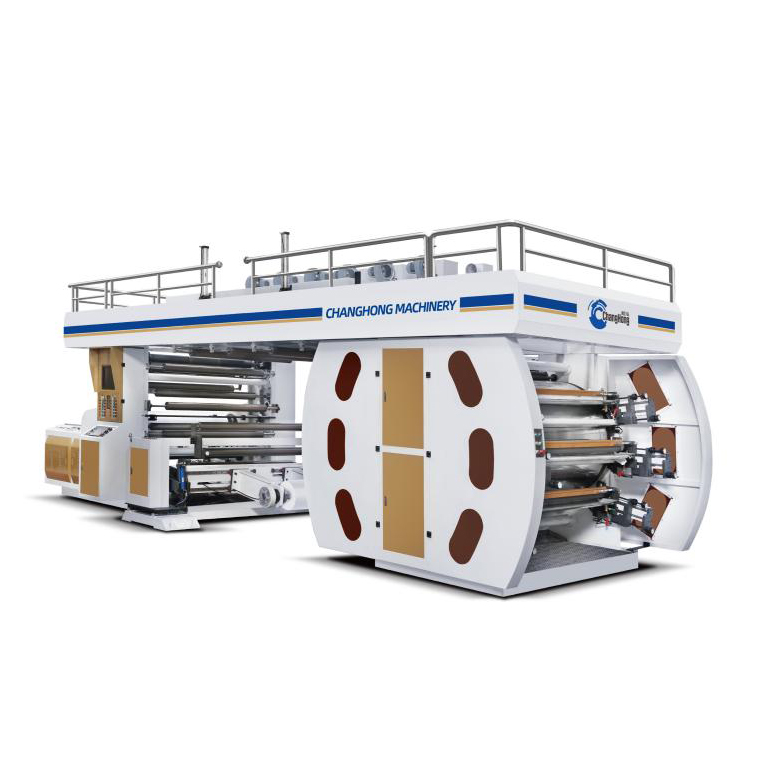

Best High Quality Bag Printing Machine Factories – Plastic film flexo printing machine – Changhong Printing

Best High Quality Bag Printing Machine Factories – Plastic film flexo printing machine – Changhong Printing

Best High Quality Bag Printing Machine Factories – Plastic film flexo printing machine – Changhong Printing Detail:

Ci flexo printing machine accounts for about 70% of the entire flexo printing machine market, most of which are used for flexible packaging printing. In addition to high overprinting accuracy, another advantage of CI flexo printing machine is the energy consumption that users should pay attention to, and the printing job can be completely dry.

|

TECHNICAL SPECIFICATIONS |

||||

| Model | CHCI4-600J | CHCI4-800J | CHCI4-1000J | CHCI4-1200J |

| Max. Web Width | 600mm | 800mm | 1000mm | 1200mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 150m/min | |||

| Printing Speed | 120m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm | |||

| Drive Type | Gear drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 400mm-900mm | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

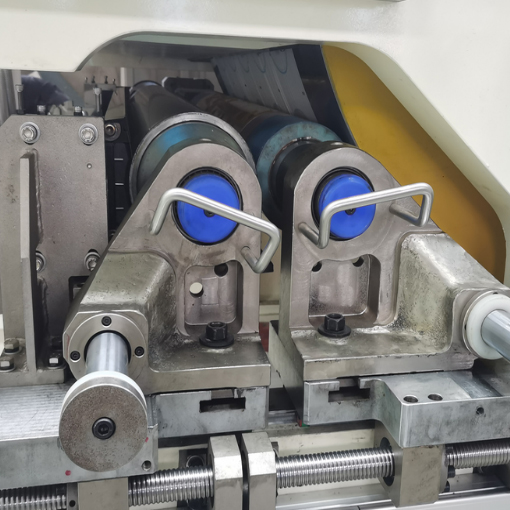

1. The short ink path ceramic anilox roller is used to transfer the ink, the printed pattern is clear, the ink color is thick, the color is bright, and there is no color difference.

2. Stable and precise vertical and horizontal registration accuracy.

3. Original imported high-precision center impression cylinder

4.Automatic temperature-controlled impression cylinder and high-efficiency drying/cooling system

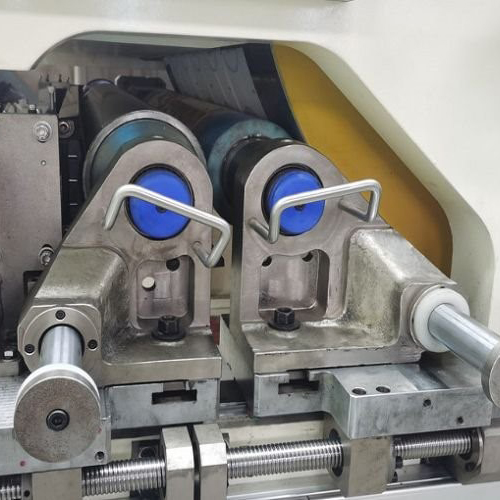

5. Closed double-knife scraping chamber type inking system

6. Fully enclosed servo tension control, the overprinting accuracy of speed up and down remains unchanged

7. Fast registration and positioning, which can achieve color registration accuracy in the first printing

1.jpg)

Product detail pictures:

Related Product Guide:

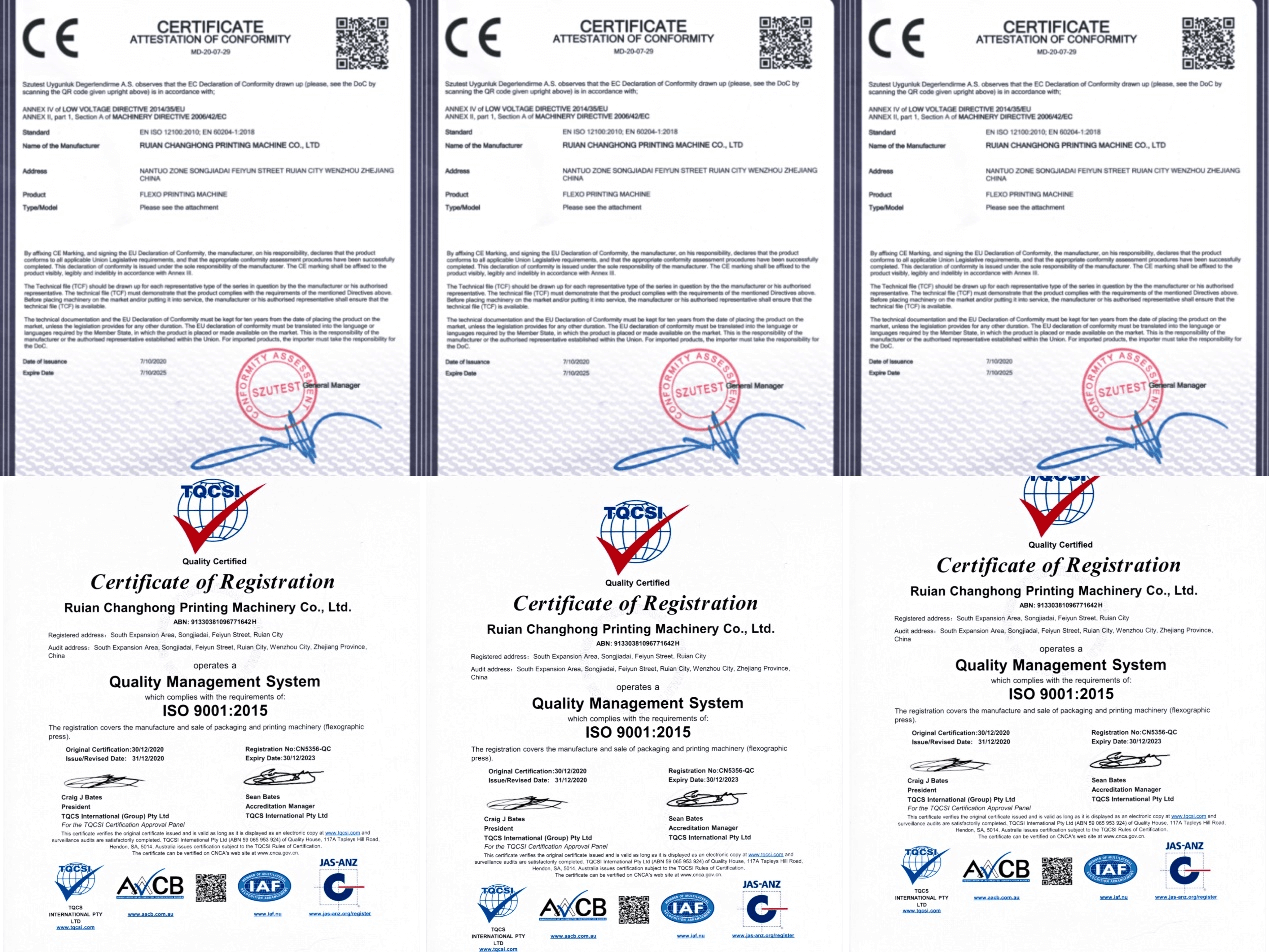

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for Best High Quality Bag Printing Machine Factories – Plastic film flexo printing machine – Changhong Printing , The product will supply to all over the world, such as: Kazakhstan, Luxemburg, Milan, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you the best service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.